Where to Start?

It all starts with Business Development. You’ve had a great idea. You’ve created an excellent Business Plan. With some effort, you’ve captured solid business financing. Now roll this video forward, imagine you have product in hand, how do you develop your customer base? While this varies from market to market, some universal fundamental steps do exist to create a strong Sales Funnel.

Business Development is the process of converting your Great Idea into a viable entity that eventually becomes self-sufficient and self-sustaining – and ever evolving. Business Development is the organic process of Building Relationships, Identifying Opportunities, Negotiating Deals, Creating a profitable Value Proposition, Developing Strategies, Creating a successful Sales & Marketing Strategy, all while ensuring one’s Great Idea is scalable and sustainable.

Testing and Qualification Protocols

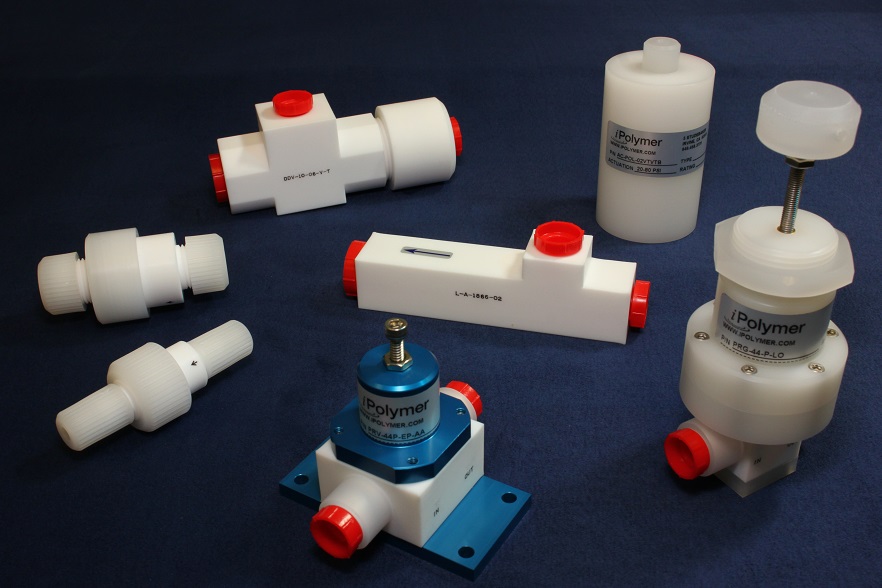

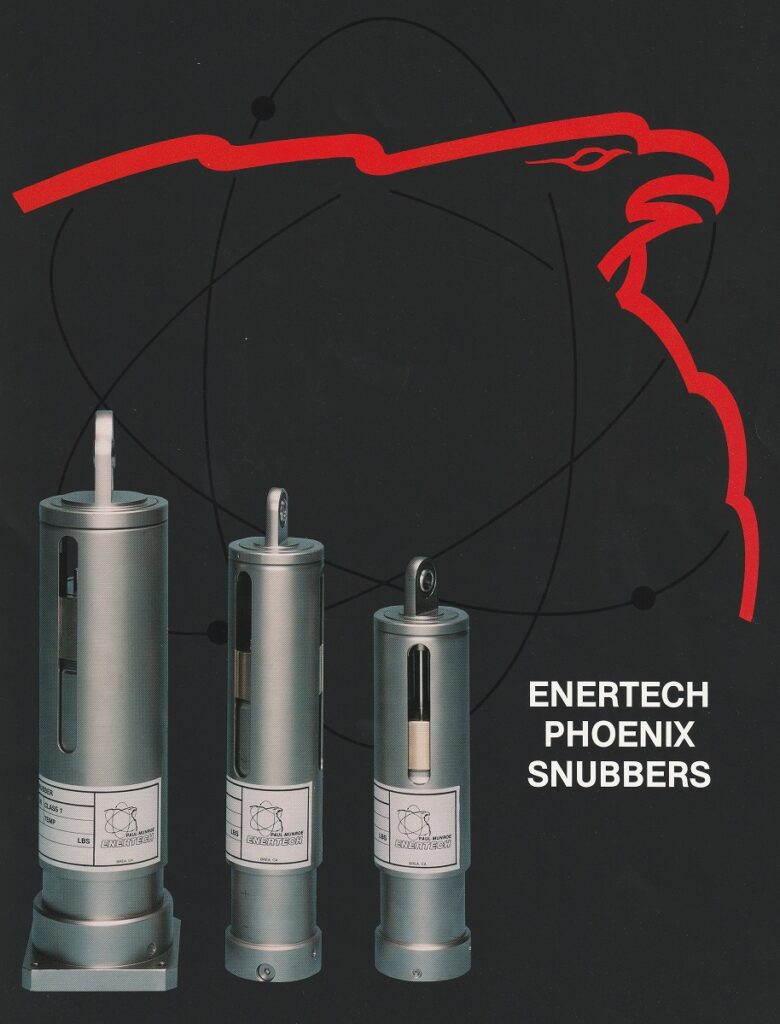

iPolymer, ENIDINE, CCI, and Enertech all had a corporate policy to aggressively performance test their products.

Well-structured Qualification Protocols and Production Test Procedures can save companies and their customers tremendous downstream headaches and stress.

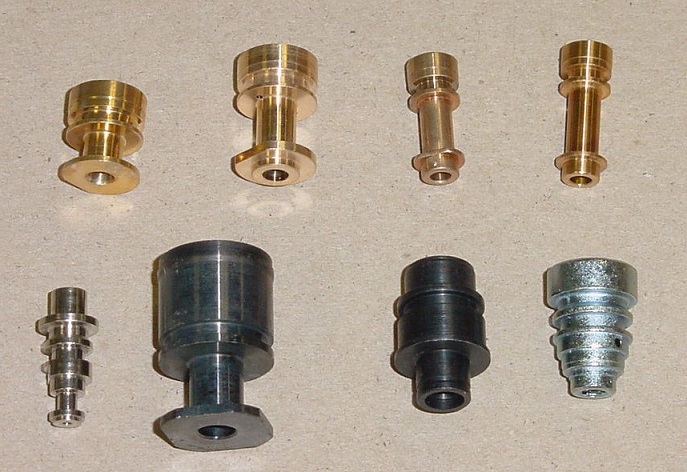

The time to find problems related to components, designs, material selections, and assembly methodologies is early in the product life cycle. Ideally, these issues should be flushed out in a robust Alpha production run (pre-production process). Prototype components should be manufactured on the same CNC machines, with the same tooling, fixtures, and cad-cam programs. This minimizes risk between prototype and production runs. The assembly and test process should follow this similar concept. Assemble with the same tooling, fixtures, and individuals. Test with the same equipment. These steps minimize risk and help to flush out design issues early in the product life cycle.

Supply Chain & Material Handling

Supply Chain Development and Management are always challenges at smaller manufacturing companies. Frequently we are working with departments of one, two, or three individuals. Both while at iPolymer and ENIDINE, I found myself deeply involved in Supply Chain Development.

The best approach is to create a Cross-Functional Team that brings to the table procurement, production, engineering, and sales. A Cross-Functional Team will bring product familiarity, component written and unwritten specification requirements, and alternatives that relate to design changes and customer acceptance.

For us, Supply Chain Development was a top corporate priority. Both iPolymer and ENIDINE leveraged top line growth by way of global sourcing. We had a full complement of CNC Machines, but those focused on short run production and prototype development. Larger runs of components were acquired from the best-in-class CNC machine shops or injection molding houses.

Total landed cost was one of the qualifying metrics. First and foremost was Quality with Delivery and Price running 2nd and 3rd in a ranked order.

Every company must optimize their inventory and material handling process to maximize their target business metrics. Too many companies try to optimize a department level without reviewing the interaction between department functions. Rarely does the management team honestly sit down and rank gross profit, revenue growth, lead time, product availability, inventory holding cost, and the cost of quality. Some of these metrics create tradeoffs within organizations, tradeoffs that affect how departments function and interact.

For both iPolymer and ENIDINE, a set of key metrics were short lead times for a broad range of products (SKUs) that represented lower annual volumes compared to, say, Automotive Industries. Our goal was to ship one of any 6,000 to 8,000 products within 2 to 6 weeks of receiving orders from our channel partners. Both companies kept their inventories at a component level state. Due to component commonality within our Bills of Materials, we were able to limit our stocked finished goods. We kept the components available for the yet-unknown future order from each product family.

Structural Projects

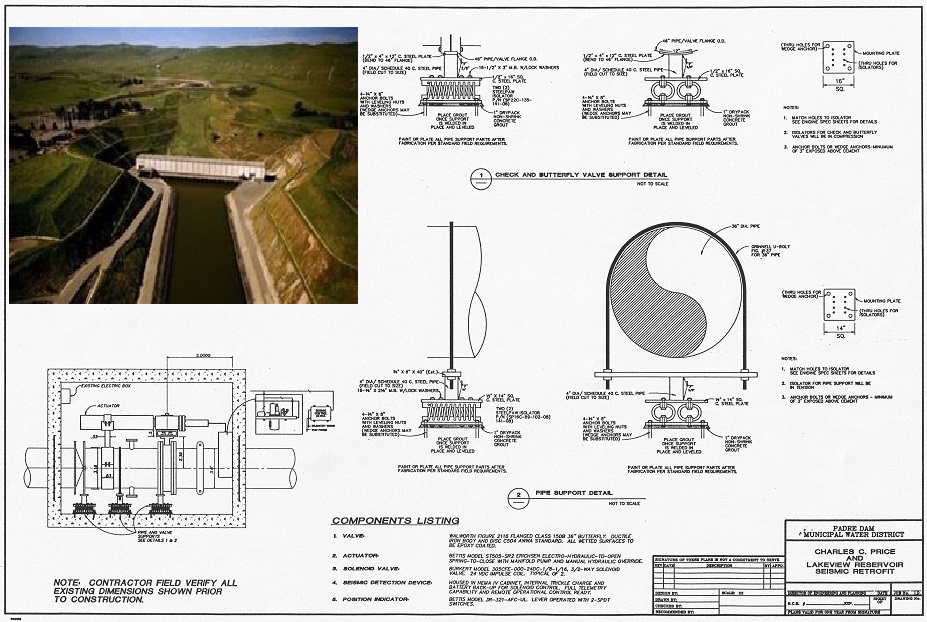

Advanced Engineering Services supported design, engineering, and project management support for Structural Projects throughout California.

Padre Dam’s reservoir valve vault was seismically isolated with wire rope isolators. The actively controlled main shutoff butterfly valve will close in the event of a major earthquake.

The Oakland Hills Firestorm of 1991 was a devastating fire event in the hilly residential area north of Oakland. Hot dry winds, called the “Diablo Winds”, added to the problem. The hillside topography created fire winds that drew through the neighborhood. Flames were fueled by dry trees and excessive foliage. Advanced Engineering Services supported the foundation and structural assessment for the demolition and reconstruction phase.

Seismic Projects

Seismic Dampers were retrofitted on the Coronado Bridge between the piers and superstructure over the shipping channel to add strategically located energy dissipation.

Twenty 300-kip by 18-inch stroke hydraulic dampers were utilized. ENIDINE Seismic Dampers were 100% tested dynamically on a special high performance test bench.

The King County Court seismic retrofit included ninety-six 150-kip by 6-inch stroke Enidine Hydraulic Dampers. These double acting linear dampers help absorb excess internal structural energy during a seismic event.

The orientation of choice is a diagonal brace configuration for building structures. For new construction projects the dampers are buried within the wall structure. However, with retrofit projects, many times the diagonal braces were exposed as shown below.

ENIDINE Seismic Damper green tagged after performance testing and final inspection.

Product Marketing – 101 Basics

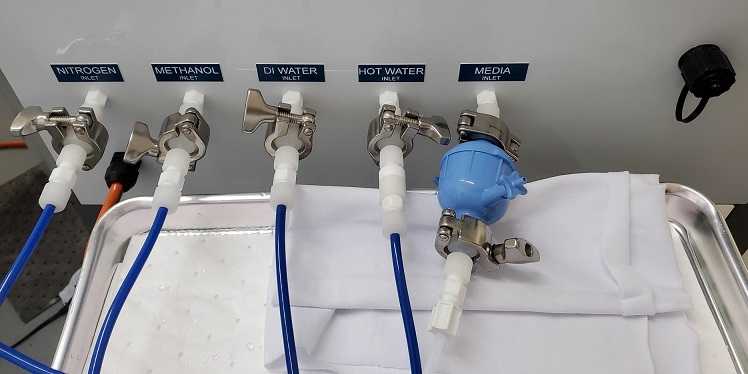

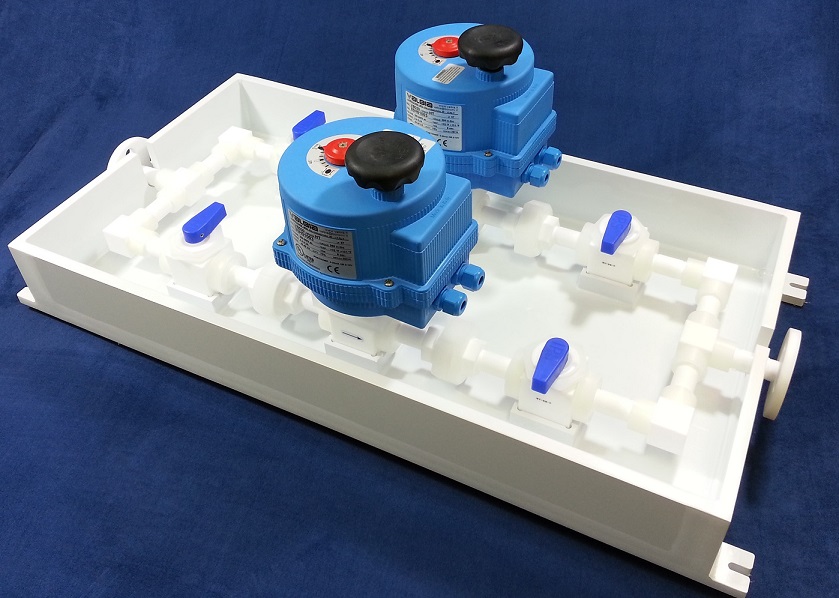

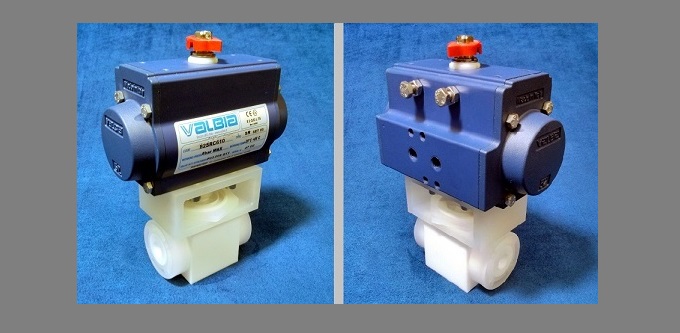

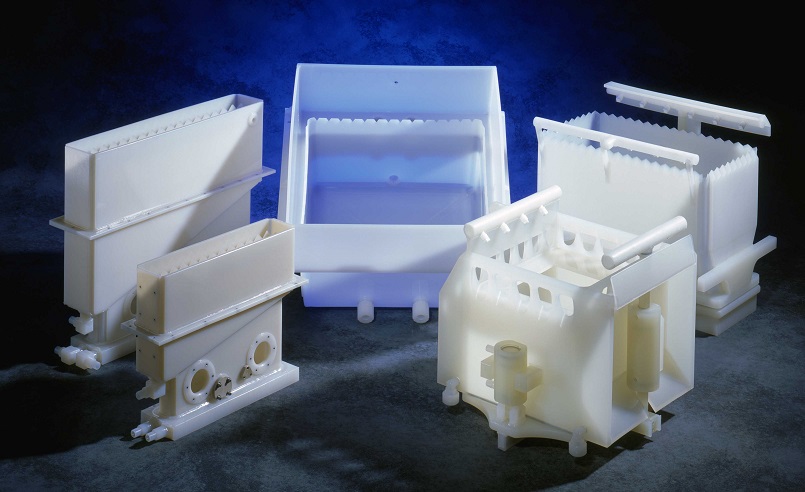

While growing iPolymer, we expanded our product overing fourfold. We combined BECO Manufacturing and TEQCOM Industries, two smaller players in the market space, combining their product lines, and drove an across-the-board upgrade/update redesign process. We then expanded our newly formed iPolymer High Purity Fluid Handling product line with key manifold products desired by the semiconductor and life sciences marketplace.

Support your sales channel with a solid Product Marketing Campaign. This includes a broad enough range of products to compel your audience to look deeper into your product offerings. While printed materials remain necessary, the market dependance on a wide range of printed material has decreased with the vast usage of the Internet. Today, you can get away with brief 4-color well written brochures. These brochures can hold QR Codes or other means to connect your audience to the detailed information retained on your website.

Product Marketing Campaigns must include supporting documentation and data to compel the client to give your product line a deeper review.

While the world of B2C have classic Early Adopter, B2B tends to be more conservative with product Adoption. A consumer (B2C person) who wants to be a trendsetter or have the latest new toy to show off in front of friends and family, will purchase with less prequalification or evaluation. Whereas, this is less true in the B2B marketplace. In the technical product B2B marketplace, the Buyer or Purchasing Agent orders what is specified by the design or manufacturing engineer. That technical person places personal risk each time he or she drifts from the norms or convention of his/her facility. In other words, early adoption is a risky proposition, one which must be justified.

Products from a family with supporting media, including, but not limited to, Qualification Reports, Certifications, Testimonials, Product Ambassadors, and Advertising Campaigns help to justify that early adoption.

These marketing materials, both printed and online, must identify and emphasize the differentiation from the alternative solutions currently in the field: longer life, lower maintenance, stronger, faster, smaller, lighter, et al. There are numerous unique application characteristics that can become selling points to win early adoption. There is always the lower price option, but be careful if lower price is your only advantage in the marketplace.

Product Family Launch

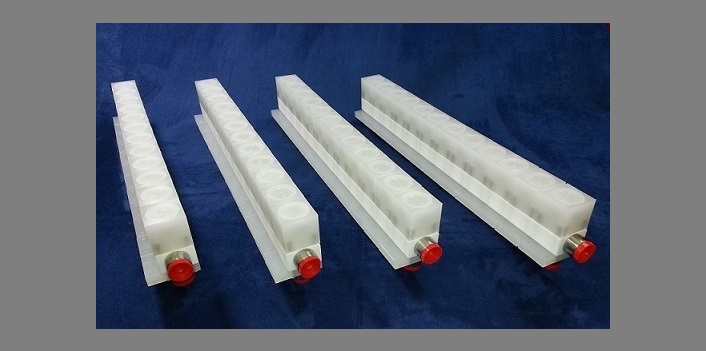

When possible, launch new products as a product family. Families appeal to a larger audience. While at Enertech, we launched the new ASME Pipe Snubber product line referred to as the Phoenix Line. The family designed to restrain power piping during emergency events, included various sizes and stroke-length pipe restraints.

The advantage that a family gives to your sales channel goes beyond a larger audience of applications. Many clients will look at this single-featured product as too new to the marketplace or too risky for initial adoption. Technical clients lean on product history and reputation.

A Product Family launch with 6, 10, 18 unique and distinct product models or SKUs, along with printed media, and online presentations, including, but not limited to, Qualification Reports, Certifications, Testimonials, Product Ambassadors, and Advertising Campaigns will stand as a product family worth adopting into the process facility.

Product Development with Voice of the Customer

Successful companies know how to develop technology and, with it, growth through profitable product families.

With an eye toward Voice of the Customer, Technology Development must always consider the market’s wants and needs.

As an Engineer myself, I recognize the value of pure and creative design efforts. The purest form of innovation has brought us amazing advancements.

But balance is necessary if you are sitting in a core industrial sector. You most likely are in a market segment with heavy global competition.

The key is Voice of the Customer. What does your customer want and need? Product Line Development and Technology Development must always include the customer’s input to help to optimize and shape your solution. Solutions that sell are valuable solutions.

As Director of Engineering and thereafter President of Enidine, we focused on valuable solutions for the marketplace.

Product Line part numbers (SKUs) from Standard Product Families will tend to grow if unchecked. Product Line Management should ensure that a logical set of business parameters are established to analyze when product expansion is appropriate. However, customization of products to meet specific customer requests (wants and needs) will always benefit the sale process. In many cases, the new product variation will be welcomed by other clients.

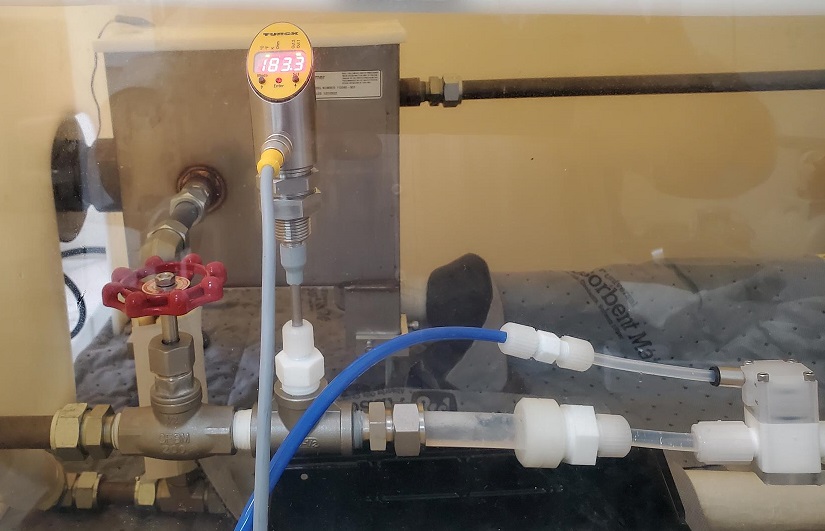

While running iPolymer, a manufacturer of High Purity Fluid Handling products, we found the spectrum of our client’s fluidic processes dictated we carry a large supporting product offering.

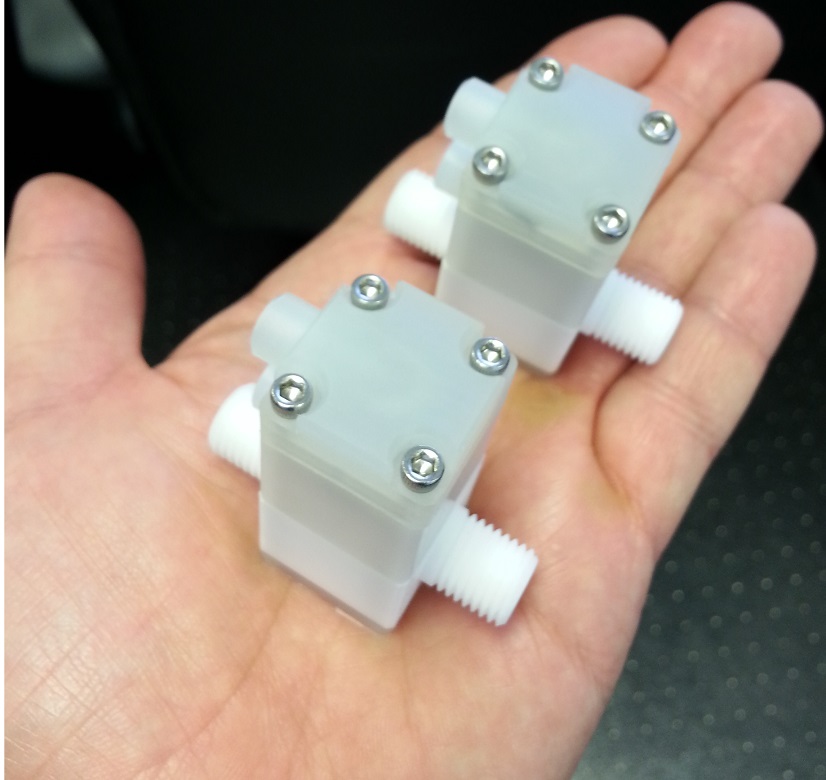

We frequently exploited the commonality of components within our Bills of Materials. One or two components would change to support our customer’s unique requirements.

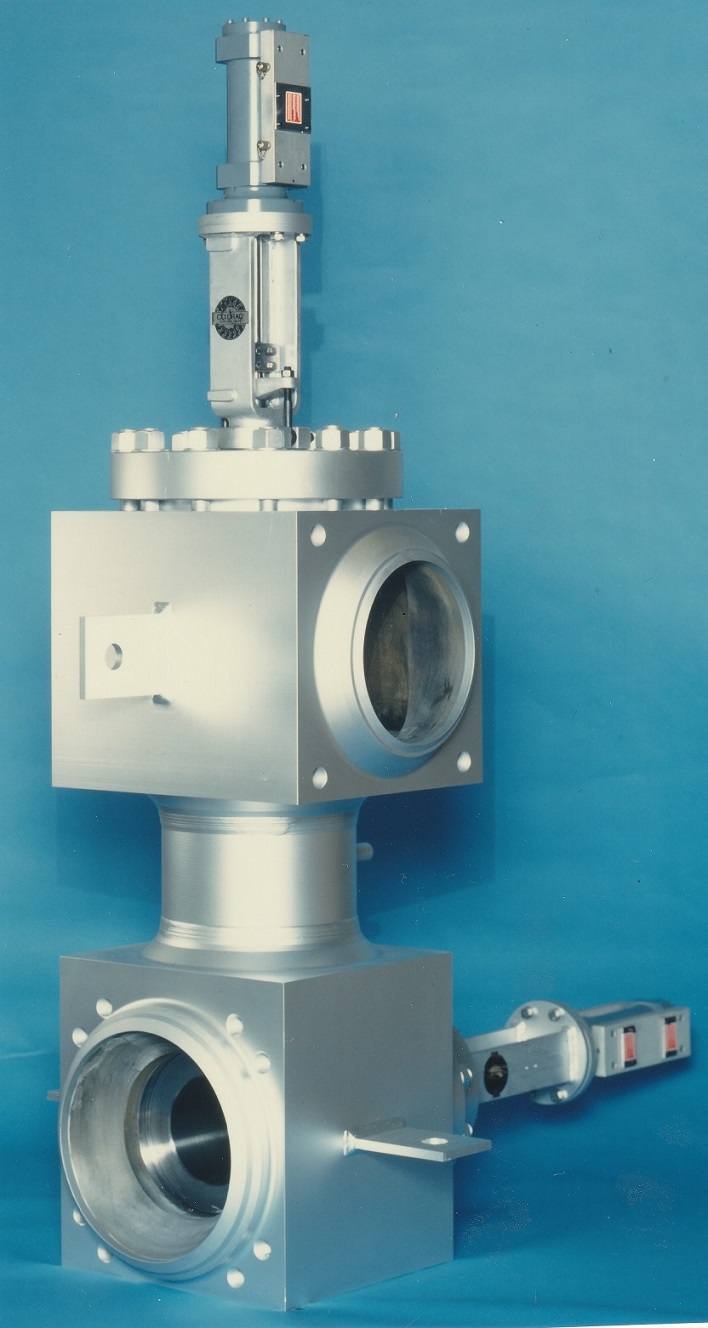

Power Gen Valve Projects

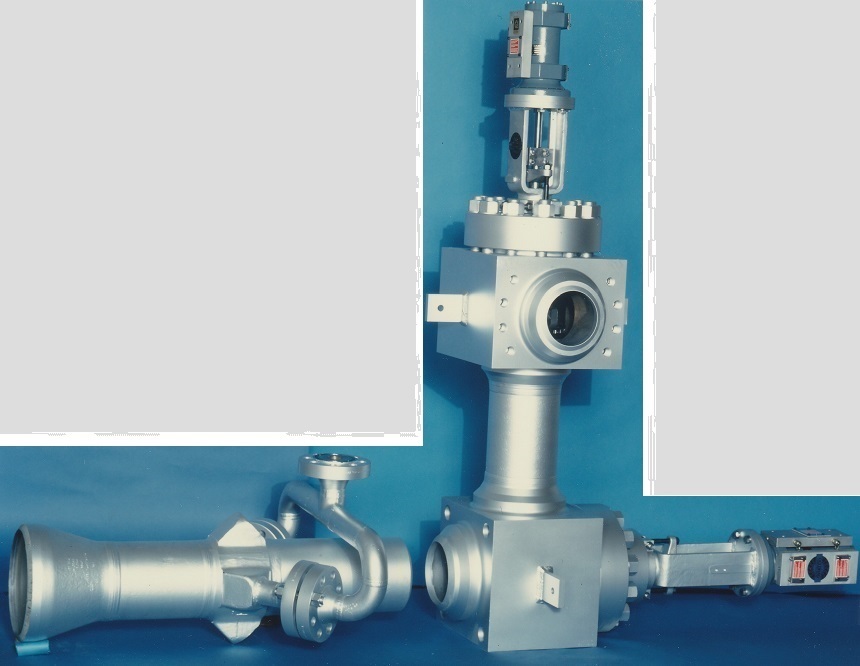

As a Project Manager for Control Components Inc., I handled multiple Power Gen Valve Projects, including Turbine Bypass Systems for Steam Generation Power Plants. The Bypass function allows the facility to quickly divert high pressure / high temperature steam to a lower state. This design feature is necessary during the startup and shutdown cycles, during transitions of electric power generation, and during emergency situations.

Turbine Bypass Valve Systems consist of a block valve, control valve, and desuperheater assembly. Typically there are three process levels: High Pressure (HP), Intermediate Pressure (IP), and Low Pressure (LP) modules. The desuperheater assembly sprays cooling water into the pressure reduced steam.

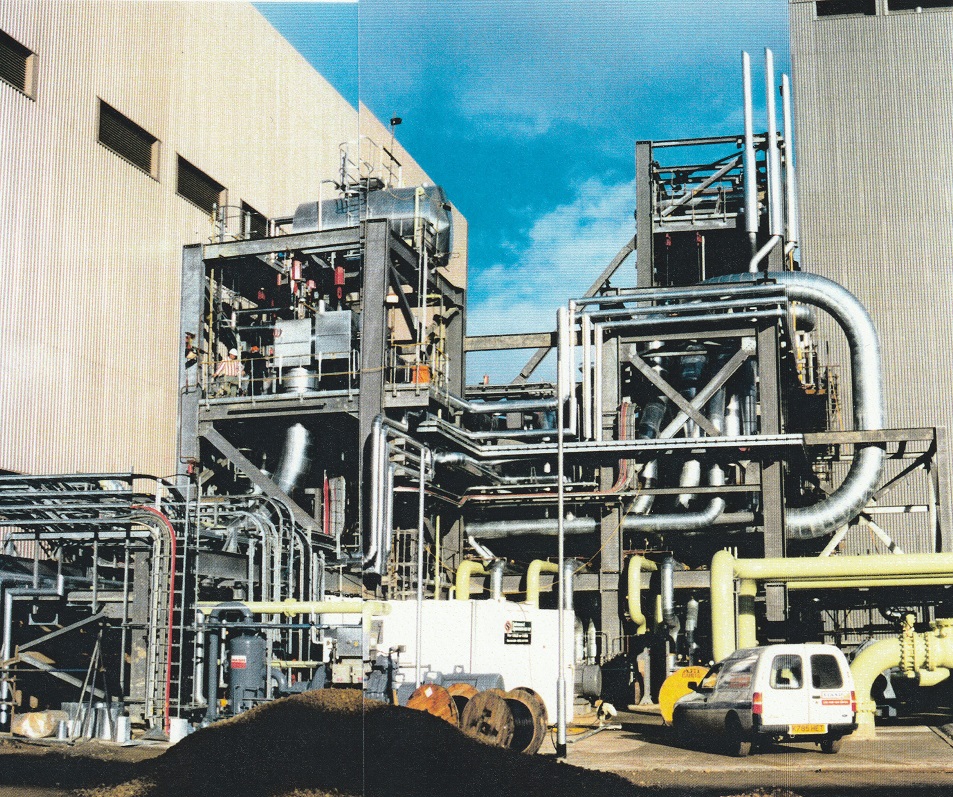

Combine Cycles Power Plants utilize waste / residual heat from a Gas Power Turbine system to generate steam. The resulting steam can then be used to drive a Steam Generator.

Little Barford UK is a Gas-Fired Power Station. Generating over 700 MW of electricity, Little Barford supplies power to the UK Grid.

The plant uses General Electric Gas Turbines, Stein Steam Generators, and Alstom Steam Turbines. These type of power plants burn much cleaner than the old Coal Fired Plants, resulting in a win for the local community and the environment.

Leverage Products into Solutions

Here is where Agile Job Shops and Entrepreneurial businesses shine: their nimble structure allows them to enhance their business topline by extrapolating their own product offering into system solutions for their clients.

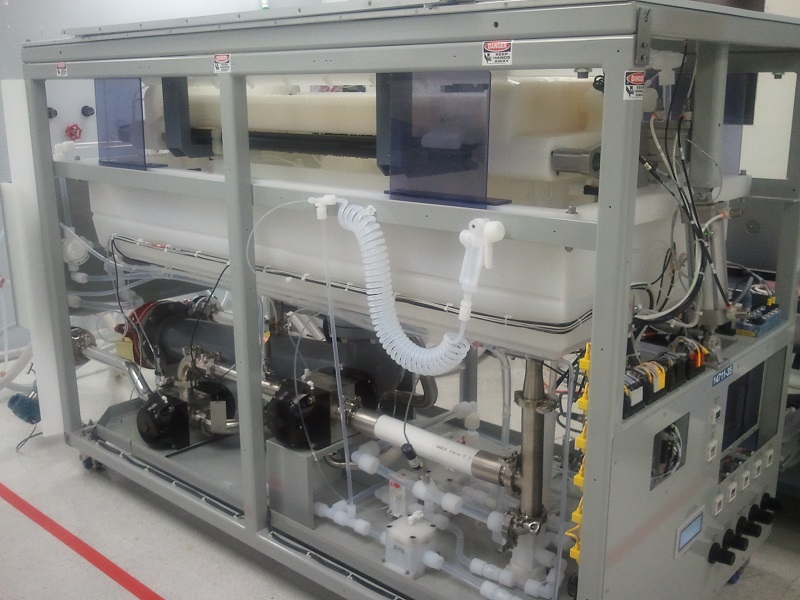

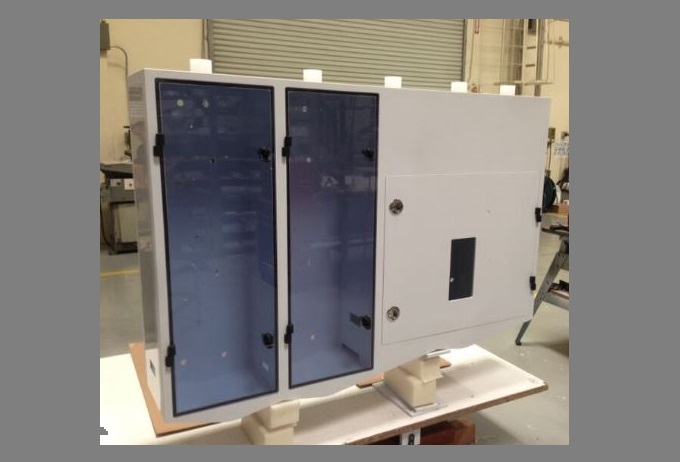

While developing our iPolymer business strategy, we elected to enhance the system and fabricated solution portion of our business. For example, if, as our client, you strictly wanted valve sets or fitting kits, we were happy to process your order. However, if you preferred, we would assemble your order (valves and fittings) into a custom valve manifold or valve stick.

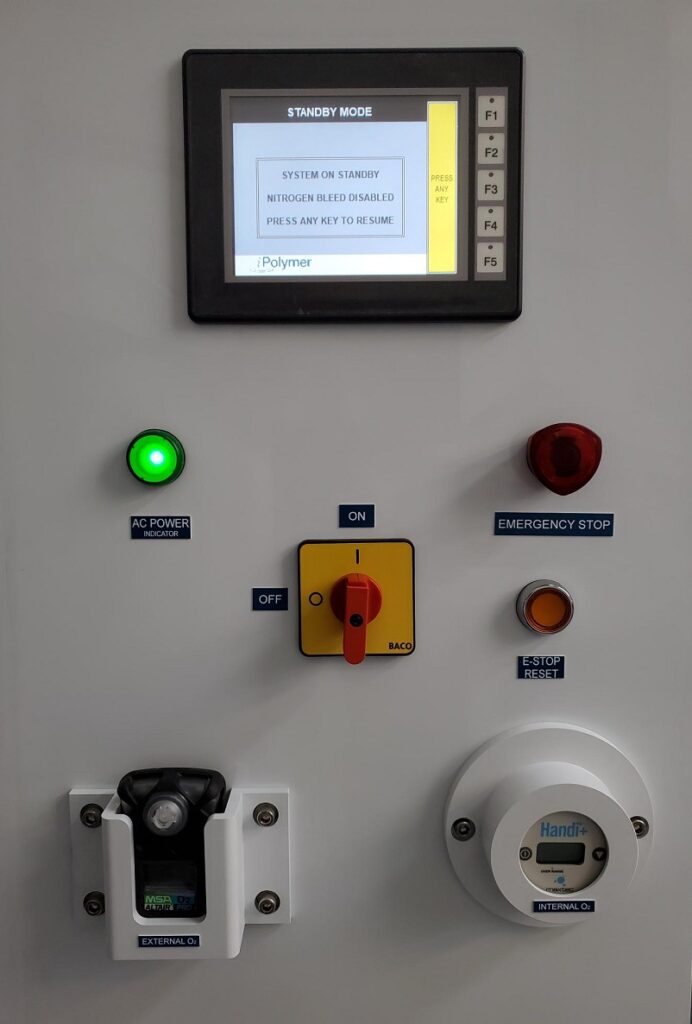

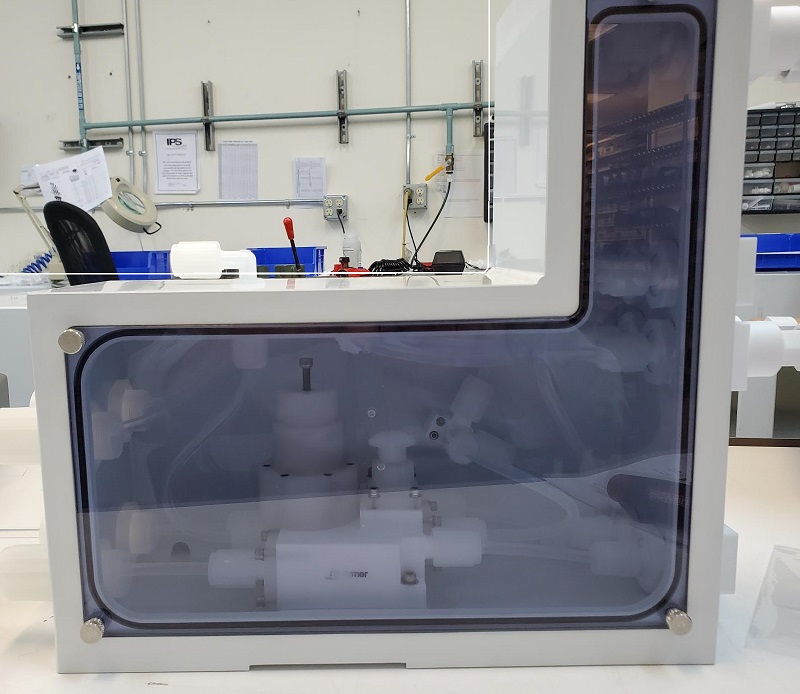

iPolymer offered Chemical Blending, Mixing, Diluting Station , as well as plumbed enclosures, which met the clients build specifications.

Lean Cellular Assembly Process

iPolymer and ENIDINE both heavily emphasized Lean Cellular Assembly in their manufacturing businesses. With low volume and high product variation, our Assembly Cells were configured for one to six employees. Each Assembly Cell was equipped with a full complement of assembly tooling, fixtures, and free-issued consumable goods.

Frequently, Operational Management must be supported and inspired to spend the extra dollars from that scarce expense budget to ensure that every Assembly Cell has all the required tooling, fixtures, and devices necessary to allow all Assemblers to stay on station. This should even include test and label devices where possible.

One key goal is to reduce physical movement of your Assembly staff. The goal is to minimize foot traffic and the need for Assemblers to ask for clarification/help. Cell Work Instructions with sufficient clarifications or an F.A.Q. database (via old school color printed binders or modern iPad/tablets computers) will assist in this process.

Agile Job Shop – Trick to Low Volume / High Variation Manufacturing

For many manufacturers, challenges arise when setting up production flow for low volume / high variation product lines. Agile Job Shops are those that can accommodate 2000 product variations with production volumes typically below 100 pieces.

Usually, these facilities develop to excel as an Agile Job Shop or they struggle and fail. Fail: with part shortages, long lead times, and/or inventory imbalances.

A combination of sound Lean Manufacturing Principles, including a blend of Visual Manufacturing Triggers with Just in Time (JIT) Processes, usually help to ensure the right components are landing in Assembly at the right time.

iPolymer was created from the merger of BECO Manufacturing and TEQCOM Industries. Any given year, iPolymer shipped over 2000 unique SKUs with most production volumes under 100 pieces. Our Manufacturing Processes were designed to ensure the correct blend of components arrived within a week or two from their required date into Assembly.

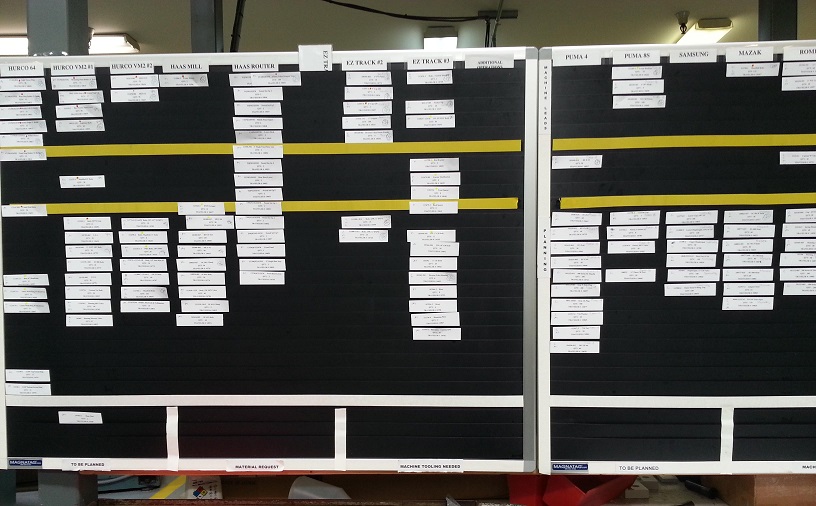

Visual Production Job Board helps enhance middle-tier ERP Systems. The visual characteristic ensures the production team senses the flow of their manufacturing process.

Breaking up the manufacturing process into individual stages with Visual Queues creates a simple roadmap to our production flow. Unique scheduling/status boards are staged at each queuing point.

Agile Job Shops, supporting high component variation at low volumes with quick lead times, require an abundance of machine Tools. Machine Tools that can be set up by one machinist in under 100-minutes significantly help the short run production model. Assuming 100-piece nominal production run: a 100-minute setup adds one minute, or less, to the Costed Bill of Material – the run time would also be added to this figure.

Acquisition Successes

May 2022: White Knight, a wholly owned subsidiary of GRACO Corporation, acquired iPolymer. iPolymer was created from the merger of BECO Manufacturing and TEQCOM Industries. Lee Capital Acquisition LLC acquired BECO in 2010 and TEQCOM in 2011. My merged team of managers helped relocate BECO and TEQCOM to our Irvine, California facility. We named the combined entity iPolymer, our focus being High Purity Fluid Handling products with an emphasis on the design and manufacturing of Teflon Valves and fluidic components.

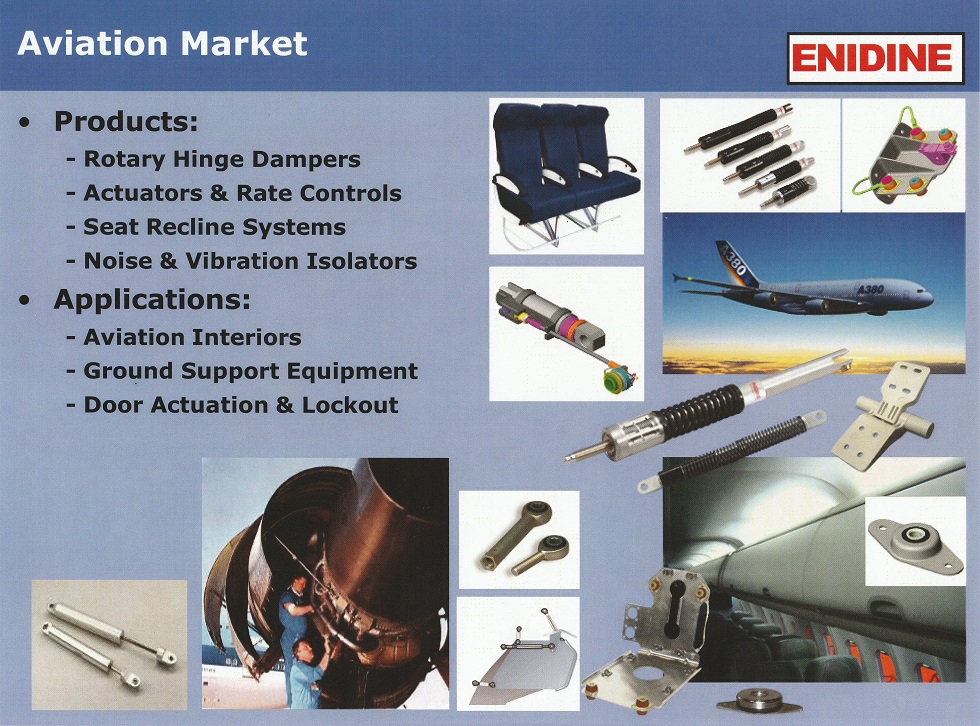

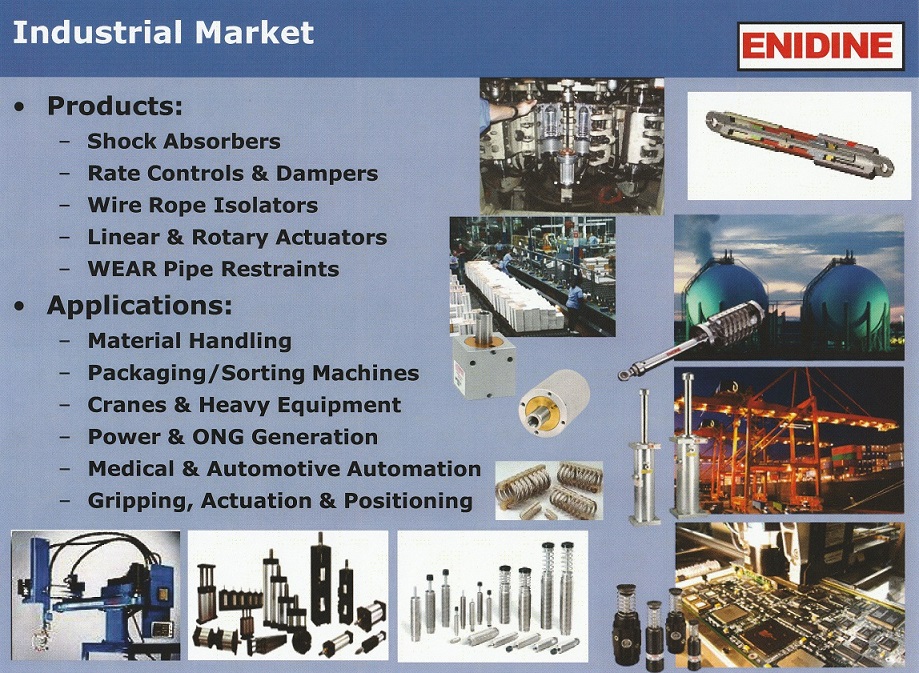

2007: ITT Corporation acquired International Motion Control (“IMC”). ENIDINE was the founding company within the IMC group of entities. ENIDINE consisted of three key markets: Aviation, Defense, and Industrial.

I grew through the ranks of ENIDINE from Seismic Program Manager, Director of Engineering, Vice President Engineering & Operations, to President of ENIDINE. During 2007, I actively supported the due diligence and divestiture of IMC to ITT. Following the sale, I remained with ITT for 2 years to assist in the integration of the IMC global entities, including ENIDINE, into ITT Corporation.