As a Project Manager for Control Components Inc., I handled multiple Power Gen Valve Projects, including Turbine Bypass Systems for Steam Generation Power Plants. The Bypass function allows the facility to quickly divert high pressure / high temperature steam to a lower state. This design feature is necessary during the startup and shutdown cycles, during transitions of electric power generation, and during emergency situations.

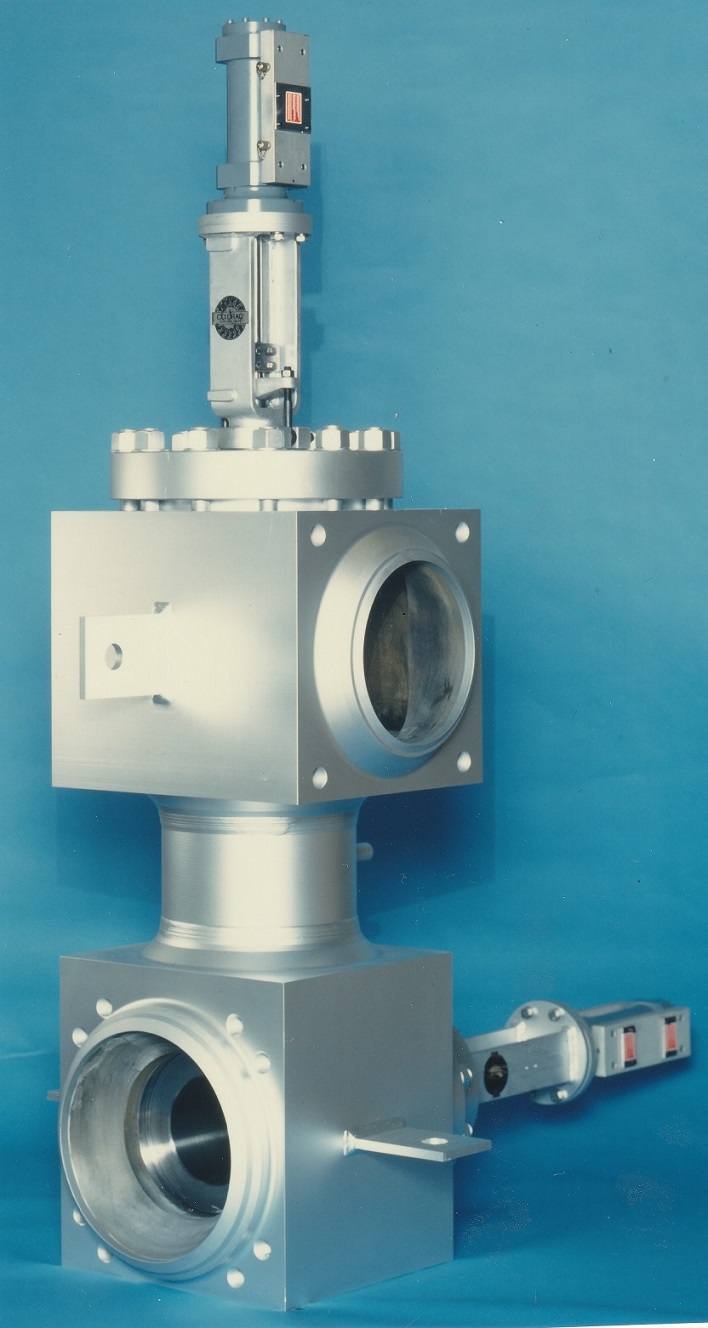

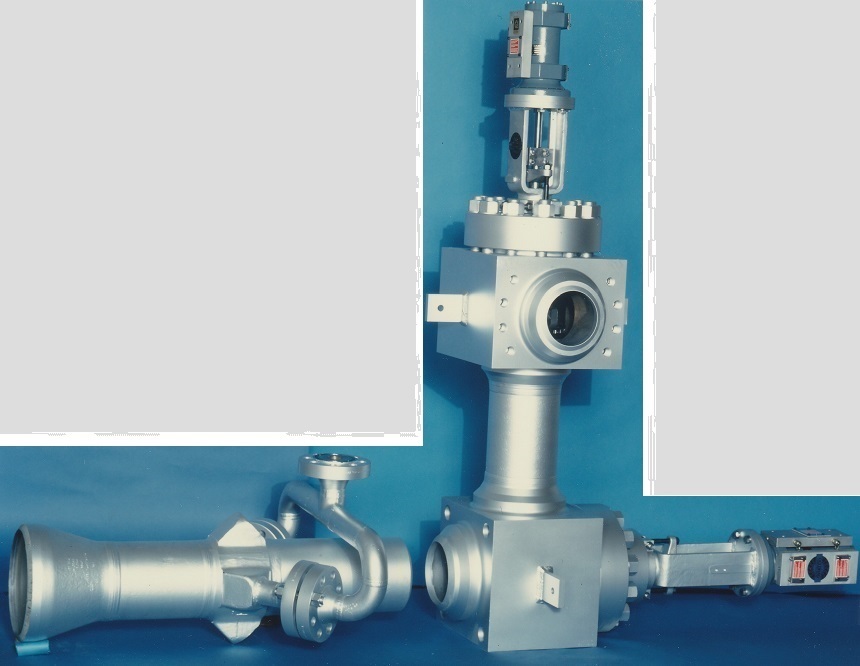

Turbine Bypass Valve Systems consist of a block valve, control valve, and desuperheater assembly. Typically there are three process levels: High Pressure (HP), Intermediate Pressure (IP), and Low Pressure (LP) modules. The desuperheater assembly sprays cooling water into the pressure reduced steam.

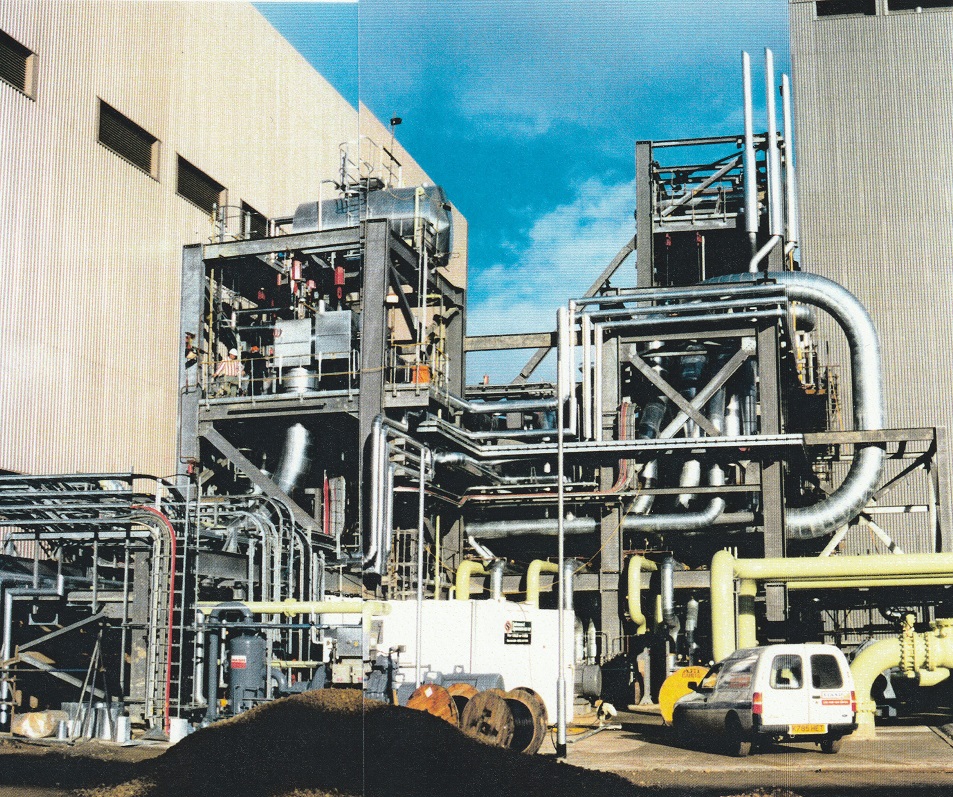

Combine Cycles Power Plants utilize waste / residual heat from a Gas Power Turbine system to generate steam. The resulting steam can then be used to drive a Steam Generator.

Little Barford UK is a Gas-Fired Power Station. Generating over 700 MW of electricity, Little Barford supplies power to the UK Grid.

The plant uses General Electric Gas Turbines, Stein Steam Generators, and Alstom Steam Turbines. These type of power plants burn much cleaner than the old Coal Fired Plants, resulting in a win for the local community and the environment.